Production Planning of Cassava Chips in Small Home Business

DOI:

https://doi.org/10.21009/JKEM.10.1.3Keywords:

cassava; chips; production; planningAbstract

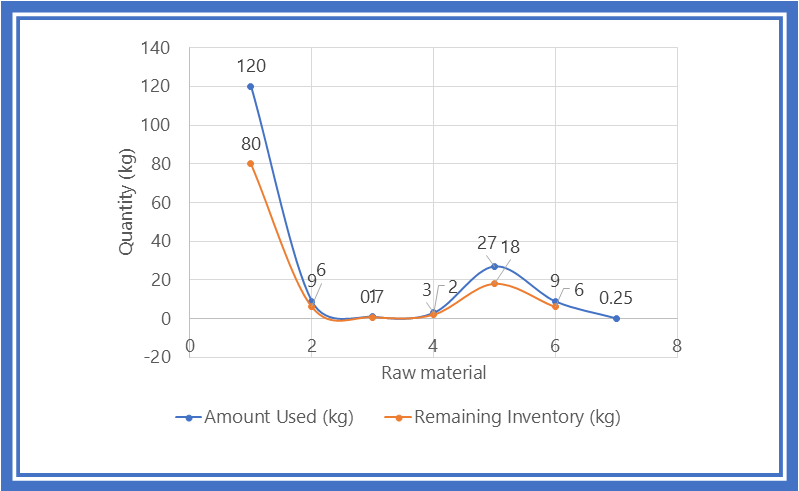

The production process of cassava chips begins with the preparation of cassava raw materials and then the process of separating the skin from cassava. The process of cutting cassava into a certain size uses a special machine that is operated manually. The process of frying cassava using a large pan and the process of packaging into plastic are the last step of production. Planning the production of cassava chips starts with preparing the needs of raw materials for production for 3 days in a week ordered from 3 different suppliers to prepare production needs, the quantity needed in purchasing from suppliers includes 120 kg of cassava, 9 kg of red chili, 1 kg of garlic, 3 kg of lime, 27 kg of cooking oil, 9 kg of sugar and 0.25 kg of salt. The initial supply of cassava raw materials provided is 120 kg and at the end of the week the production inventory needs are 80 kg left from the use of 40 kg at the end of the week for the next production.

References

[1] O. Vincent, N. O. Ijedinma, and U. C. Onyemachi, “Production planning and organizational effectiveness,” SJBSS, vol. 1, pp. 1–28, 2018.

[2] M. A. Ikon and C. N. Nwankwo “Production planning and profitability of selected manufacturing firms in nigeria,” IJBMR, vol. 4, no. 1, pp. 11-32, 2016.

[3] C. Grönroos and K. Ojasalo, “Service productivity: towards a conceptualization of the transformation of inputs into economic results in services,” J. Bus. Res., vol. 57, no. 4, pp. 414-423, 2004, doi: 10.1016/S0148-2963(02)00275-8.

[4] A. P. Kinanthi, D. Herlina, and F. A. Mahardika, “Analisis pengendalian persediaan bahan baku menggunakan metode min-max (studi kasus PT. Djitoe Indonesia Tobacco),” Performa: Media Ilmiah Teknik Industri, vol. 15, no. 2, 2016, doi: 10.20961/performa.15.2.9824.

[5] M. Bashiri, H. Badri, and J. Talebi, “A new approach to tactical and strategic planning in production–distribution networks,” Appl. Math. Model., vol. 36, no. 4, pp. 1703-1717, doi: 10.1016/j.apm.2011.09.018.

[6] A. E. Nyoko, R, P. Fanggidae, and Y. Y. Marawali, “The forecasting of raw material inventory in support of the continuity production process,” Journal of Management: SMEs, vol. 16, no. 3, pp. 517-530, 2023, doi: 10.35508/jom.v16i3.12633.

[7] A. Taufiq and A. Slamet, “Pengendalian persediaan bahan baku dengan metode economic order quantity (EOQ) pada salsa bakery jepara,” MAJ, vol. 3, no. 1, pp. 1-6, 2014 doi: 10.15294/maj.v3i1.3355.

[8] H. Alshenqeeti, “Interviewing as a data collection method: a critical review,” Engl. Linguist. Res., vol. 3, no. 1, pp. 39-45, 2014, doi:10.5430/elr.v3n1p39.

[9] O. Vincent, N. O. Ijedinma, and U. C. Onyemachi, “Production planning and organizational effectiveness,” SJBSS, vol. 1, pp. 1–28, 2018.

[10] Y. B. Priliyanto and Y. B. S. Sumiyati, “Perancangan ulang tata letak penyimpanan barang menggunakan metode dedicated storage (studi kasus: PT. temprina media grafika,” Tekmapro J. Ind. Eng. Manag., vol. 14, no. 1, pp. 17–25, 2019.

[11] A. Lestari and N. A. Mahbubah, “Analisis defect proses produksi songkok berbasis metode FMEA dan FTA di home-industri songkok GSA Lamongan,” JSE, vol. 6, no. 3, pp. 2197-2206, 2021.

[12] M. C. Tuerah, “Analisis pengendalian persediaan bahan baku ikan tuna pada CV. golden KK,” Jurnal EMBA, vol. 2, no. 4, pp. 524-536, 2015, doi: 10.35794/emba.2.4.2014.6360.

[13] J. Puspika, and D. Anita, “Inventory control dan perencanaan persediaan bahan baku produksi roti pada pabrik roti bobo pekanbaru,” J. Ekonomi, vol. 21, no. 3, pp. 1-15, 2013.

[14] T. M., Barwa, “Inventory control as an effective decision - making model and implementations for company’s growth,” IJEFM, vol. 3, no. 5, pp. 465-472, 2015, doi: 10.11648/j.ijefm.20150305.18.

[15] P. Fithri and A. Sindikia “Pengendalian persediaan pozzolan di PT semen padang,” JOSI, vol. 13, no. 2, pp. 665-686, 2014.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuyun Yuniar Rohmatin, Rossi Septy Wahyuni, Mei Raharja, Siva Fauzia

This work is licensed under a Creative Commons Attribution 4.0 International License.