Analysis of Print Speed Variations Effect and Nozzle Temperature on the Tensile Strength of 3D Printed TPU-95A Products

DOI:

https://doi.org/10.21009/JKEM.10.1.6Keywords:

additive manufacturing; material testing; printing parameters; mechanical propertiesAbstract

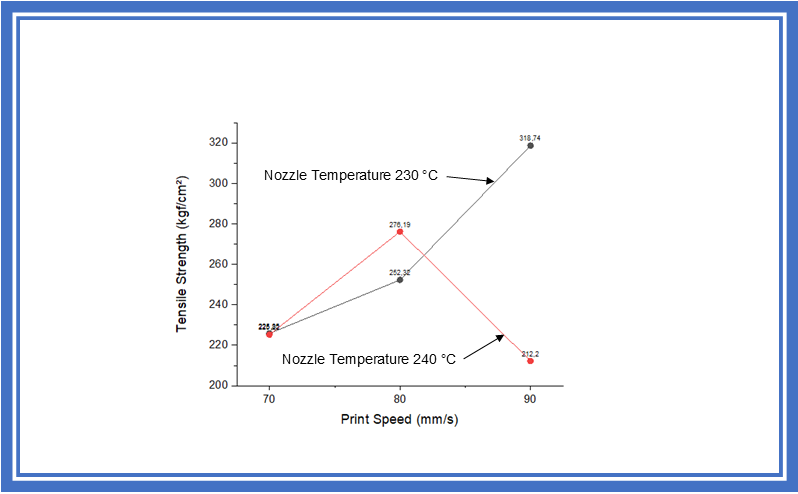

This study aims to analyze the effect of print speed and nozzle temperature variations on the tensile strength of TPU-95A material printed using the fused deposition modeling (FDM) method. The varied parameters include print speeds (70, 80, and 90 mm/s) and nozzle temperatures (230 and 240 °C). Tensile test specimens were produced using an Ender-3 Pro 3D printer according to the JIS K6251-2017 standard and tested with a Shimadzu AGS-X 10kN tensile testing machine. The results showed that the combination of a 90 mm/s print speed and a 230 °C nozzle temperature yielded the highest tensile strength of 318.74 kgf/cm². Conversely, the lowest tensile strength of 212.20 kgf/cm² occurred at a 90 mm/s print speed and a 240 °C nozzle temperature due to thermal degradation of the material. This study highlights the importance of selecting optimal printing parameters to enhance the mechanical strength of 3D-printed products made from TPU-95A.

References

[1] S. Cahyati and Y. A. Furqon, “The layer height variations effect on tensile strength of 3D printing product PLA material based”, JRM, vol. 13, no. 3, pp. 647–657, 2022, doi: 10.21776/jrm.v13i3.823.

[2] Z. S. Suzen, “Pengaruh tipe infill dan temperatur nozzle terhadap kekuatan tarik produk 3d printing filamen PLA+ esun,” Manutech: Jurnal Teknologi Manufaktur, vol. 12, no. 02, pp. 73-80, 2020, doi: 10.33504/manutech.v12i2.133

[3] D. Mardiyana, Z. Sulaiman, S. Ihsan, F. Ridha, and T. Rahman, “Rancang bangun 3D printer FDM model cartesian berbasis arduino,” JMPM, vol. 7, no. 1, pp. 63–72, 2023, doi: 10.18196/jmpm.v7i1.16866.

[4] R. Rosalina, M. Subhan, and P. Pristiansyah, “Pengaruh parameter proses pada pencetakan 3D printing terhadap akurasi dimensi filamen PETG menggunakan metode taguchi,” JITT, vol. 2, no. 1, p. 79-87, 2024, doi: 10.33504/jitt.v2i1.149.

[5] J. Pratama and A. Z. Adib, “Pengaruh parameter cetak pada nilai kekerasan serta akurasi dimensi material thermoplastic elastomer (TPE) hasil 3D printing,” JIG, vol. 25, no. 1, pp. 35-44, 2022, doi: 10.47313/jig.v%vi%i.1712.

[6] J. Xiao and Y. Gao, “The manufacture of 3D printing of medical grade TPU,” Prog. Addit. Manuf., vol. 2, pp. 117–123, 2017, doi: 10.1007/s40964-017-0023-1.

[7] V. Marco, G. Massimo, and G. Manuela, “Additive manufacturing of flexible thermoplastic polyurethane (TPU): enhancing the material elongation through process optimisation,” Prog. Addit. Manuf., 2024, doi: 10.1007/s40964-024-00790-y.

[8] A. S. Putri, B. W. Karuniawan, and F. Rachman, “Analisis pengaruh variasi parameter 3d printing terhadap kekuatan tarik, kekuatan impak, dan building time menggunakan metode taguchi–grey relational analysis,” in Proceedings Conference on Design Manufacture Engineering and Its Application, vol. 6, no. 1, 2022.

[9] A. A. Ansari and M. Kamil, “Effect of print speed and extrusion temperature on properties of 3D printed PLA using fused deposition modeling process,” in Mater. Today Proc., vol. 45, pp. 5462–5468, 2021, doi: 10.1016/j.matpr.2021.02.137.

[10] J. Panjaitan, M. Tampubolon, F. Sihombing, and J. Simanjuntak, “Pengaruh kecepatan, temperatur dan infill terhadap kualitas dan kekasaran kotak relay lampu sign sepedamotor hasil dari 3D printing”, Sprocket Journal of Mechanical Engineering, vol. 2, no. 2, pp. 87-99, Feb. 2021, doi: 10.36655/sproket.v2i2.530.

[11] T. C. Yang, & C. H. Yeh, “Morphology and mechanical properties of 3D printed wood fiber/polylactic acid composite parts using fused deposition modeling (FDM): the effects of printing speed,” Polymers, vol. 12, no. 6, p. 1334, 2020, doi: 10.3390/polym12061334.

[12] R. A. Supriyadi, V. A. Setyowati, and A. A. Rosidah, “Pengaruh jumlah layer dan orientasi sudut filler karbon pada polymer matrix composite terhadap kekuatan tarik dan impact,” in Prosiding SENASTITAN: Seminar Nasional Teknologi Industri Berkelanjutan, vol. 1, no. 1, pp. 264-271, 2021.

[13] B. Arifvianto, T. N. Iman, B. T. Prayoga, R. Dharmastiti, U. A. Salim, M. Mahardika, and Suyitno, “Tensile properties of the FFF-processed thermoplastic polyurethane (TPU) elastomer,” Int. J. Adv. Manuf. Tech., vol. 117, no.5, pp. 1709-1719, 2021, doi: 10.1007/s00170-021-07712-0.

[14] D. Mardiyana, D. I. Sumarno, M. A. S. Yudono, and L. A. Islami, “Kajian kelayakan sifat mekanik produk 3D printing FDM berfilamen eFlex TPU-95A untuk aplikasi polisi tidur,” JRM, vol. 19, no. 3, pp. 457-468, 2024, doi: 10.32497/jrm.v19i3.5966.

[15] R. A. Nanda, R. Oktapian, and M. T. Ulhakim, “Penerapan Simulasi Finite Element Terhadap Material Polylactic Acid Untuk Aplikasi Deker Kaki,” ARMATUR: Artikel Teknik Mesin dan Manufaktur, vol. 5, no. 2, 2024, doi: 10.24127/armatur.v5i2.5533.

[16] A. Chadha, M. I. U. Haq, A. Raina, R. R. Singh, N. B. Penumarti, and M. S. Bishnoi, “Effect of fused deposition modelling process parameters on mechanical properties of 3D printed parts,” World J. Eng., vol. 16, no. 4, pp. 550–559, 2019, doi: 10.1108/WJE-09-2018-0329.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Triadesman Gulo, Dani Mardiyana, Dodi Iwan Sumarno

This work is licensed under a Creative Commons Attribution 4.0 International License.