Analysis of the Effect of Print Speed and Layer Height on the Hardness of TPU-95A Filament 3D-Printed Products

DOI:

https://doi.org/10.21009/JKEM.10.1.2Keywords:

3D printing; hardness; layer height; printing speed; TPU-95AAbstract

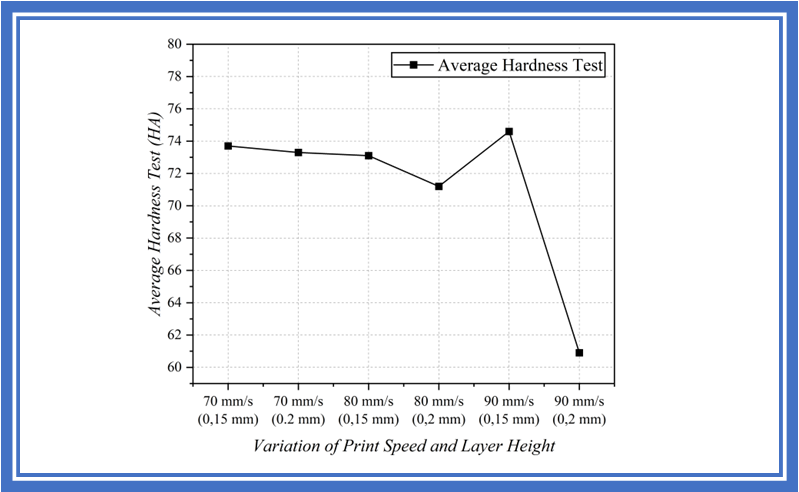

The effect of print speed and layer height settings can influence the mechanical properties of 3D-printed products; however, the impact of print speed and layer height on the hardness of products printed with TPU-95A filament has not been extensively studied. This research employs an experimental method by creating specimens according to ASTM D2240 standards, using various print speed settings (70, 80, and 90 mm/s) and layer heights (0.15 and 0.20 mm). The results show that a combination of lower print speeds and thinner layer heights yields higher hardness test results. A print speed of 90 mm/s and a layer height of 0.15 mm produced the highest hardness, while the combination of 90 mm/s print speed and 0.2 mm layer height resulted in the lowest hardness. This study contributes to the optimization of 3D printing parameters for flexible material applications, such as TPU-95A, in relation to product hardness outcomes.

References

[1] D. Mardiyana, Z. Sulaiman, S. Ihsan, F. Ridha, and T. Rahman, “Rancang bangun 3D printer FDM model cartesian berbasis arduino,” JMPM, vol. 7, no. 1, pp. 63–72, 2023, doi: 10.18196/jmpm.v7i1.16866.

[2] T. D. Ngo, A. Kashani, G. Imbalzano, K. T. Nguyen, and D. Hui, “Additive manufacturing (3D printing): a review of materials, methods, applications and challenges,” Compos. Part B Eng., vol. 143, pp. 172-196, 2018, doi: 10.1016/j.compositesb.2018.02.012.

[3] S. Vyavahare, S. Teraiya, D. Panghal, and S. Kumar, “Fused deposition modelling: a review,” Rapid Prototyp. J., vol. 26, no. 1, pp. 176-201, 2020, doi: 10.1108/RPJ-04-2019-0106.

[4] G. S. Lubis, M. Taufiqurrahman, and M. Ivanto, “Analisa pengaruh parameter proses terhadap uji kekerasan produk hasil 3D printing berbahan polylatic acid,” J. Engine Energi, Manufaktur, dan Mater., vol. 5, no. 2, p. 39, 2021, doi: 10.30588/jeemm.v5i2.877.

[5] B. Shaqour, M. Abuabiah, S. Abdel-Fattah, A. Juaidi, R. Abdallah, W. Abuzaina, M. Qarout, B. Verleije and P. Cos, “Gaining a better understanding of the extrusion process in fused filament fabrication 3D printing: a review,” Int. J. Adv. Manuf. Tech.,” vol. 114, pp. 1279-1291, 2021, doi: 10.1007/s00170-021-06918-6.

[6] I. Ibrahim, A. G. Ashour, W. Zeiada, N. Salem, and M. Abdallah, “A systematic review on the technical performance and sustainability of 3D printing filaments using recycled plastic,” Sustainability, vol. 16, no. 18, p. 8247, 2024, doi: 10.3390/su16188247.

[7] M. Dylan, A. Soewono, and M. Darmawan, “Analisis laju aliran pada nozzle printer tiga dimensi untuk material thermoplastic polyurethane,” Cylinder: Jurnal Ilmiah Teknik Mesin, vol. 8, no. 1, pp. 1–7, 2022, doi: 10.25170/cylinder.v8i1.3907.

[8] A. P. Valerga, M. Batista, J. Salguero, and F. Girot, “Influence of PLA filament conditions on characteristics of FDM parts,” Materials (Basel)., vol. 11, no. 8, 2018, doi: 10.3390/ma11081322.

[9] R. A. Sandika, “Studi kelayakan soft mold yang dicetak menggunakan teknologi fused filament fabrication (FFF) bermaterial thermoplastic polyurethane (TPU) pada proses vacuum infusion untuk pembuatan produk komposit,” pp. 1–47, 2022.

[10] P. Pristiansyah, H. Hardiansyah, and S. Sugiyarto, “Optimasi parameter proses 3D printing FDM terhadap akurasi dimensi menggunakan filament Eflex,” Manutech J. Teknol. Manufaktur, vol. 11, no. 1, pp. 33–40, 2019, doi: 10.33504/manutech.v11i01.98.

[11] F. Bähr and E. Westkämper, “Correlations between influencing parameters and quality properties of components produced by fused deposition modeling,” in Procedia CIRP, vol. 72, pp. 1214–1219, 2018, doi: 10.1016/j.procir.2018.03.048.

[12] A. Zamheri, F. Arifin, and I. Apriansyah, “Pengaruh parameter pada proses 3D printing menggunakan filament eal-fill terhadap akurasi dimensi dan kekerasan dengan pendekatan metode taguchi,” Machine: J. Tek. Mesin, vol. 7, no. 2, pp. 30–34, 2021.

[13] M. F. A. R. Ghifari, S. Aisyah, and H. Toar, “Desain mesin filament extruder,” J. Integr., vol. 14, no. 2, pp. 145–152, 2022, doi: 10.30871/ji.v14i2.4673.

[14] E. Paz, M. Jiménez, L. Romero, M. del M. Espinosa, and M. Domínguez, “Characterization of the resistance to abrasive chemical agents of test specimens of thermoplastic elastomeric polyurethane composite materials produced by additive manufacturing,” J. Appl. Polym. Sci., vol. 138, no. 32, p. 50791, 2021, doi: 10.1002/app.50791.

[15] K. Rajan, M. Samykano, K. Kadirgama, W. S. W. Harun, and M. M. Rahman, “Fused deposition modeling: process, materials, parameters, properties, and applications,” Int. J. Adv. Manuf. Technol., vol. 120, no. 3, pp. 1531-1570, 2022, doi: 10.1007/s00170-022-08860-7.

[16] R. Kristiawan, F. Imaduddin, D. Ariawan, Ubaidillah, and Z. Arifin, “A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters,” Open Eng., vol. 11, no. 1, pp. 639-649, 2021, doi: 10.1515/eng-2021-0063.

[17] M. Hikmat, S. Rostam, and Y. M. Ahmed, “Investigation of tensile property-based taguchi method of PLA parts fabricated by FDM 3D printing technology,” Results Eng., vol. 11, p. 100264, 2021, doi: 10.1016/j.rineng.2021.100264.

[18] H. Gonabadi, A. Yadav, and S. J. Bull, “The effect of processing parameters on the mechanical characteristics of PLA produced by a 3D FFF printer,” Int. J. Adv. Manuf. Technol., vol. 111, pp. 695–709, 2020, doi: 10.1007/s00170-020-06138-4.

[19] J. Pratama and A. Z. Adib, “Pengaruh parameter cetak pada nilai kekerasan serta akurasi dimensi material thermoplastic elastomer (TPE) hasil 3D printing,” J. Ilm. Giga, vol. 25, no. 1, pp. 35-44, 2022, doi: 10.47313/jig.v25i1.1712.

[20] L. Di Angelo, P. Di Stefano, A. Dolatnezhadsomarin, E. Guardiani, and E. Khorram, “A reliable build orientation optimization method in additive manufacturing: the application to FDM technology,” Int. J. Adv. Manuf. Technol., vol. 108, pp. 263–276, 2020, doi: 10.1007/s00170-020-05359-x.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Rizal Lesmana, Dani Mardiyana, Dodi Iwan Sumarno

This work is licensed under a Creative Commons Attribution 4.0 International License.