Analysis of Corrosion Rate in Low-Carbon Steel ASTM A36 and AISI 1020 in Sulfuric Acid Solution Using Heat Treatment Temperature and Immersion Time Variations

DOI:

https://doi.org/10.21009/JKEM.10.1.5Keywords:

corrosion rate; heat treatment; low-carbon steel; sulfuric acid; immersion timeAbstract

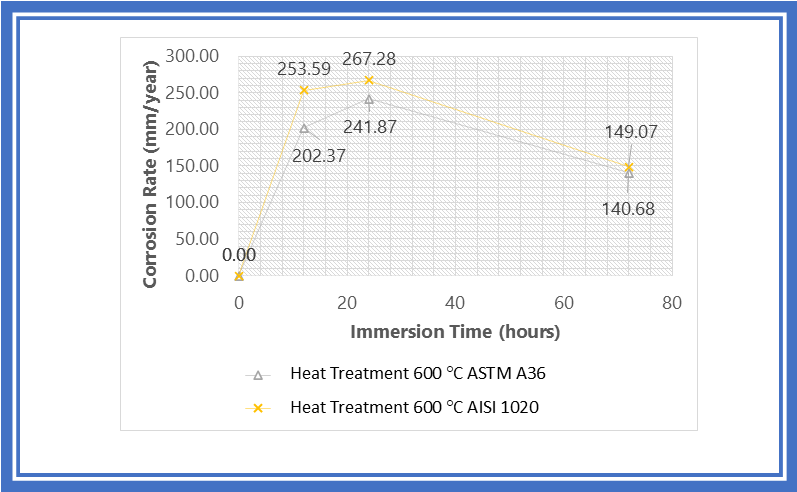

This study investigates the corrosion rate of low-carbon steel ASTM A36 and AISI 1020 in sulfuric acid solution under varying heat treatment temperatures and immersion times. Samples were subjected to heat treatment at 600, 820, and 1100 °C, followed by immersion for 24, 48, and 72 hours. The results reveal significant effects of heat treatment temperature and immersion duration on corrosion performance. At 600 °C with a 72-hour immersion, ASTM A36 exhibited a corrosion rate of 140.68 mm/year, while AISI 1020 showed 149.07 mm/year. At 820 °C, the corrosion rates for ASTM A36 and AISI 1020 were 102.34 mm/year and 96.48 mm/year, respectively. At 1100 °C, ASTM A36 demonstrated a corrosion rate of 87.97 mm/year, compared to 121.08 mm/year for AISI 1020. The findings highlight that increasing heat treatment temperature generally reduces the corrosion rate, though the effect varies by material.

References

[1] V. Kumar, N. Sharma, S. K. Tiwari, and S. Kango, “Atmospheric corrosion of materials and their effects on mechanical properties: a brief review,” in Mater. Today Proc., vol. 44, pp. 4677-4681, 2021, doi: 10.1016/j.matpr.2020.10.939.

[2] D. H. Xia, C. M. Deng, D. Macdonald, S. Jamali, D. Mills, J. L. Luo, M. G. Strebl, M. Amiri, W. Jin, S. Song, and W. Hu, “Electrochemical measurements used for assessment of corrosion and protection of metallic materials in the field: a critical review,” J. Mater. Sci. Technol., vol. 112, pp. 151-183, 2022, doi: 10.1016/j.jmst.2021.11.004.

[3] M. M. Hasan, A. Rahman, A. Islam, and M. A. H. Khondoker, “Strengthening transformer tank structural integrity through economic stiffener design configurations using computational analysis,” Appl. Mech., vol. 5, no. 4, pp. 717-730, 2024, doi: 10.3390/applmech5040039.

[4] W. C. D., Silva, R. M. D. Nascimento, N. A. Castro, and C. L. M. Silva, “Microstructural analysis of partially diluted zones in dissimilar cladding: EBSD insights on AWS E 309L alloy via MIG process in single-and double-layer depositions on ASTM A36 steel,” Mater. Res., vol. 27, p.e20230442, 2024, doi: 10.1590/1980-5373-MR-2023-0442.

[5] A. Rahui, M. Allouch, and M. Alami, “Study of the impact of TIG welding parameters and post-weld heat treatment on the bending properties of AISI 1020 steel welded joints,” Weld. Int., vol. 38, no. 7, pp. 451–463, 2024, doi: 10.1080/09507116.2024.2358228.

[6] M. A. Wahid, A. N. Siddiquee, and Z. A. Khan, “Aluminum alloys in marine construction: characteristics, application, and problems from a fabrication viewpoint,” Mar. Syst. Ocean Technol., vol. 15, no. 1, pp. 70-80, 2020, doi: 10.1007/s40868-019-00069-w.

[7] O. Zurita, V. Di-Graci, and M. Capace, “Effect of cutting parameters on surface roughness in turning of annealed AISI-1020 steel,” Rev. Fac. Ing., vol. 27, no. 47, pp. 121-128, 2018.

[8] C. Martínez, F. Briones, M. Villarroel, and R. Vera, “Effect of atmospheric corrosion on the mechanical properties of SAE 1020 structural steel,” Materials, vol. 11, no. 4, p. 591, 2018, doi: 10.3390/ma11040591.

[9] A. A. Ayoola, R. Babalola, B. M. Durodola, E. E. Alagbe, O. Agboola, and E. O. Adegbile, “Corrosion inhibition of A36 mild steel in 0.5 M acid medium using waste citrus limonum peels,” Results in Eng., vol. 15, p. 100490, 2022, doi: 10.1016/j.rineng.2022.100490.

[10] T. Tuovinen, P. Tynjälä, T. Vielma, and U. Lassi, “Utilization of waste sodium sulfate from battery chemical production in neutral electrolytic pickling,” J. Clean. Prod., vol. 324, p. 129237, 2021, doi: 10.1016/j.jclepro.2021.129237.

[11] D. W. Yun, S. M. Seo, H. W. Jeong, and Y. S. Yoo, “The effects of the minor alloying elements Al, Si and Mn on the cyclic oxidation of Ni–Cr–W–Mo alloys,” Corros. Sci., vol. 83, pp. 176-188, 2014, doi: 10.1016/j.corsci.2014.02.015.

[12] M. Ahangar, M. Izadi, T. Shahrabi, and I. Mohammadi, “The synergistic effect of zinc acetate on the protective behavior of sodium lignosulfonate for corrosion prevention of mild steel in 3.5 wt% NaCl electrolyte: surface and electrochemical studies,” J. Mol. Liq., vol. 314, p. 113617, 2020, doi: 10.1016/j.molliq.2020.113617.

[13] S. Zheng, X. Wang, G. Qin, and Z. Zhu, “Mechanism of directional reduction strengthening of nickel laterite ore under fluidization condition,” Metall. Mater. Trans. B, vol. 55, pp. 4929–4941, 2024, doi: 10.1007/s11663-024-03311-y.

[14] A. H. Ettefagh, S. Guo, and J. Raush, J. “Corrosion performance of additively manufactured stainless steel parts: A review,” Addit. Manuf., vol. 37, p. 101689, 2021, doi: 10.1016/j.addma.2020.101689.

[15] A. Polkowska, S. Lech, P. Bała, and W. Polkowski, “Microstructure and mechanical properties of Ni-Fe-Cr-Al wrought alumina forming superalloy heat-treated at 600–1100° C,” Mater. Charact., vol. 171, p. 110737, 2021, doi: 10.1016/j.matchar.2020.110737.

[16] Sopiyan, Syaripuddin, M. H. Fatahillah, M. F. P. Putra, and M. Y. Hasbi, “Pengaruh titanium dalam lapisan las terhadap struktur makro-mikro, kekerasan, dan laju korosi”, J. Konv. Ener. Manuf., vol. 9, no. 2, pp. 104 – 111, 2024, doi: 10.21009/JKEM.9.2.2.

[17] M. Z. Z. Mazlan and Z. Kamdi, “A review of wear and corrosion for carbide-coating on different method: HVOF thermal spray and electrodeposition method,” RPMME, vol. 2, no. 2, pp. 121-129, 2021.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Trisna Ardi Wiradinata, Asy'ari Daryus, Didik Sugiyanto, Nopryandi, Muhammad Ikhsan

This work is licensed under a Creative Commons Attribution 4.0 International License.